Highlights 2023

DURACON® POM Accelerates

DURACON® POM Accelerates

Next-Generation Initiatives

As manufacturing has evolved rapidly in recent years,

there is an increasing need for human resources who can generate innovation

and support future manufacturing growth strategies.

In Japan, however, there are concerns about a shortage of human resources for future manufacturing,

due to the declining birthrate and aging population,

and due to many young people losing interest in science.

As an engineering plastic manufacturer,

Polyplastics was also faced with the important task of fostering the next generation who have a manufacturing mindset.

Lighter, Faster Machines Improved with DURACON® POM

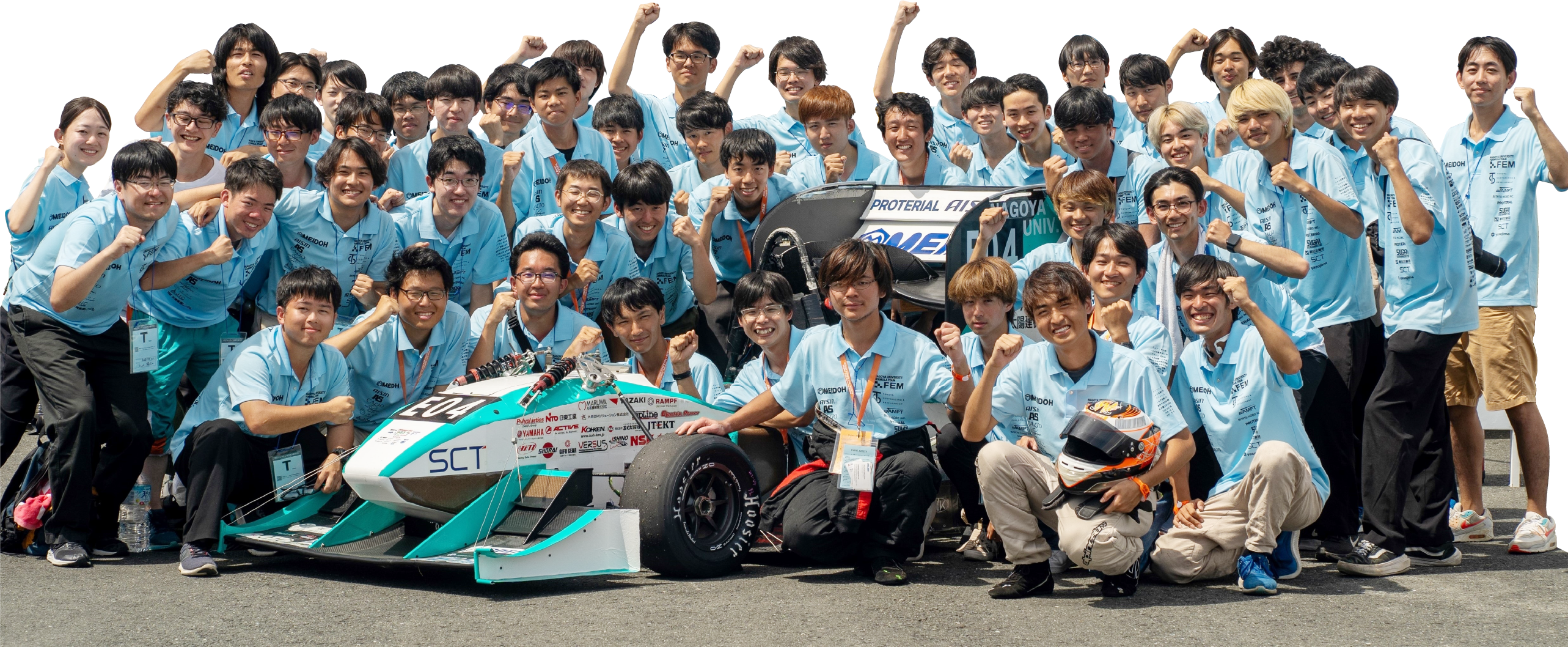

In 2011, we first met the Nagoya University Formula Team “FEM”. FEM is a strong team that has won the overall championship in the Student Formula Competition. The purpose of the Student Formula Competition is to foster future engineers. Teams organized by students spend a year designing and building a formula-type racing machine. In this competition, they compete not only in driving time, but also in comprehensive skills such as planning, technical skills, and safety. FEM was one of the first teams in Japan to shift to EVs (Electric Vehicles), and has taken on the challenge of advanced initiatives such as the use of “4-wheel in-wheel motors,” in which each wheel is controlled by an independent motor. Our product DURACON® POM, an engineering plastic that is lighter than metal and easier to cut, was selected as a way to further reduce the weight of the car body.

FEM was founded in November 2003 and achieved its long-awaited overall championship victory in the 12th competition in 2014 in a gasoline-powered vehicle. After that, inspired by the acceleration performance of EVs used by overseas teams, FEM has been competing using EVs since 2017 to compete on the world stage. From 2017 to 2021, FEM won the Overall Excellence Award in the EV category four consecutive times, and the same award again in 2023.

| 2014 | Overall Championship Victory |

|---|---|

| 2017-2021 | EV Overall Excellence Award (4th consecutive win) |

| 2023 | EV Overall Excellence Award |

Supporting Overall Championship Victories with EVs

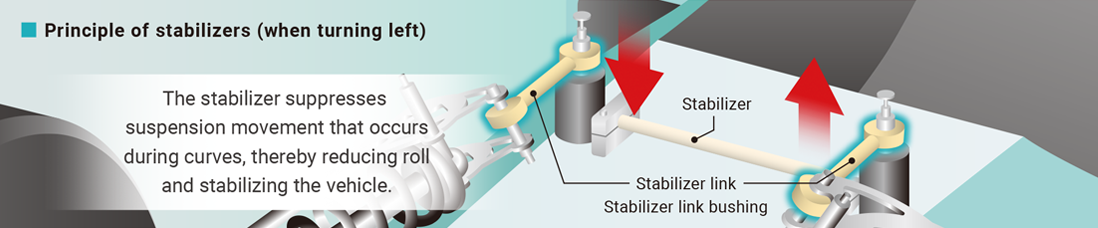

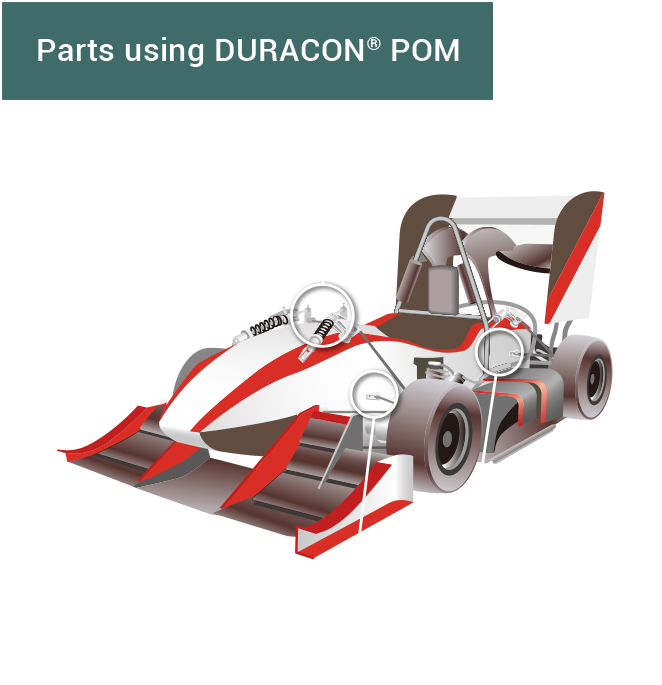

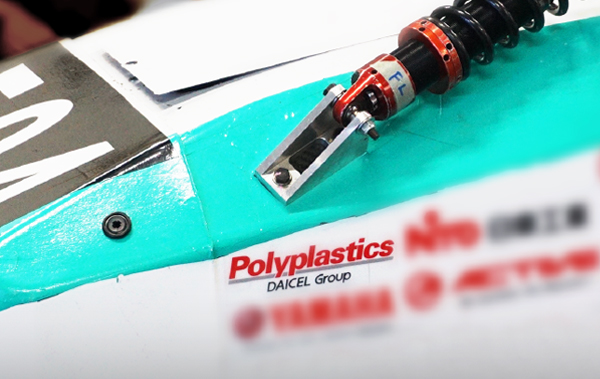

DURACON is used in several places in FEM machines, one of which is stabilizer bearing parts. Because EVs tend to go faster when cornering, the body and tires tend to tilt, making it difficult to stabilize the vehicle’s driving. That makes the performance of stabilizers, which keep the vehicle body level, vitally important. Using DURACON, which has a low coefficient of friction and is very slippery, for the bearing portion of the stabilizer, FEM was able to suppress the tilting of the vehicle body and achieve stable driving.

FEM aims to become the first team in history to win the overall championship with an EV. They believe that the key to victory is to reduce the weight of the machine body and to improve the stability of the machine’s operation, which is currently a major issue. They will be working on progress in manufacturing and machine design aspects, including the use of engineering plastics. We will continue to support the initiatives of FEM, which embraces the manufacturing mindset and the spirit of taking on challenges, by providing further engineering plastics solutions.

Expectations for use in EVs

As it has excellent fuel resistance, DURACON has been used in many fuel system parts of combustion vehicles.

Although internal combustion system (engine) parts may disappear with the shift to EV vehicles, the heavier batteries in Evs will make it necessary to reduce weight in other parts more than ever. Therefore, while the demand for engine parts will decrease, there will be new room for DURACON to play an active role in parts such as radiators.

Developing the manufacturing mindset in the next generation is an important social issue, not only in Japan but around the world as well. In addition to our ongoing support for FEM, we will continue to promote the appeal of engineering plastics to the world and actively work to foster the next generation interested in manufacturing.

Nagoya University Formula Team "FEM"