Highlights 2024

DURACIRCLE® Launched : Toward

DURACIRCLE® Launched : Toward

100% Engineering Plastic Recycling

The rise in extreme weather and natural disasters has made climate change a major global challenge. As decarbonization laws globally advance, stricter regulations are expected beyond 2030, urging companies to adopt environmentally-friendly products. In FY 2024, we launched DURACIRCLE® to meet these environmental demands and drive sustainability through innovation in engineering plastics.

Our Commitment to Challenge as the Leader in Engineering Plastics

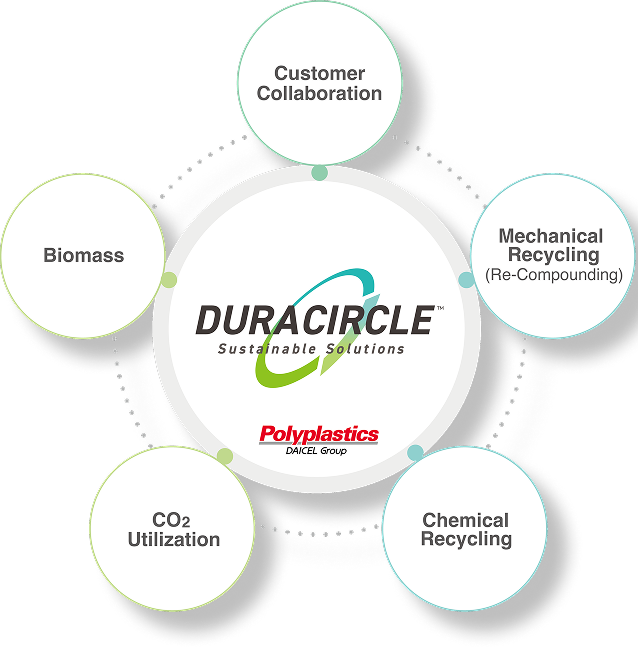

As a leading company in engineering plastics, we are deeply committed to the challenge of achieving 100% circularity. Our DURACIRCLE initiative embodies this determination, aiming to co-create sustainable value with our customers. Through the expansion of mechanical recycling, chemical recycling, biomass utilization, CO2 utilization and all related environmentally-friendly products, technologies, and services, DURACIRCLE represents our unwavering dedication to building a more sustainable future together.

DURA, derived from Durable, highlights the strength and longevity of engineering plastics. Combining this with CIRCLE, a term evocative of the concept of a cycle, forms the name DURACIRCLE.

In the past, we have introduced such products as DURACON® bG-POM and LAPEROS® bG-LCP, which we consider environmental solutions meant to be achieved through biomass. This time, we are introducing environmental initiatives with a focus on recycling.

Major Challenges in Recycling Processes

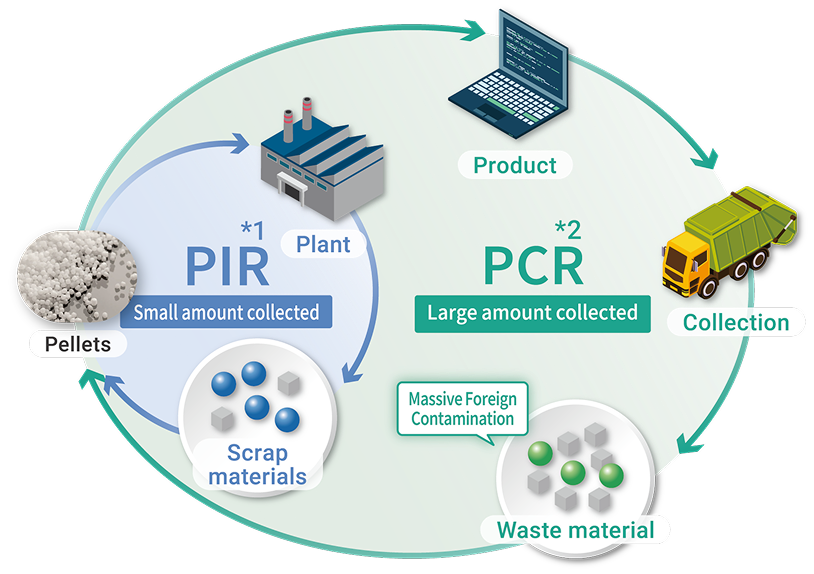

Recycling—recovering waste plastics and reusing them as raw materials for new products—can make a significant contribution to reducing environmental impact. However, this process faces several major challenges, including securing sufficient quality and quantity of collected materials, degradation of resin performance due to repeated use, and contamination from impurities such as dirt and metal particles.

Moreover, as recycling efforts expand from industrial waste to general household waste, the level of contamination in waste plastics increases, making reuse even more difficult. This growing complexity presents another significant hurdle in achieving effective and sustainable recycling.

*1 PIR: Post-Industrial Recycling: Recycling of scrap materials and other materials generated in the manufacturing process prior to delivery to the final consumer

*2 PCR: Post-Consumer Recycling: Recycling of items after they have been delivered to the final consumer

Providing Solutions for the Recycling of Engineering Plastics

We have begun a recompounding service and commenced developing resins based on the use of PCR-derived recycled raw materials as one possible solution for the recycling of engineering plastics to address the challenges that such recycling poses.

Recompounding Service

This service is an initiative through which the sprues, runners, and other molding scraps that are generated in customers’ manufacturing processes are not discarded but are instead collected and ground by us and recompounded or made into pellets to become new products.

By using this recycled material as a raw material, we can reduce the amount of virgin material used while maintaining product quality and even help lower the carbon footprint of products.

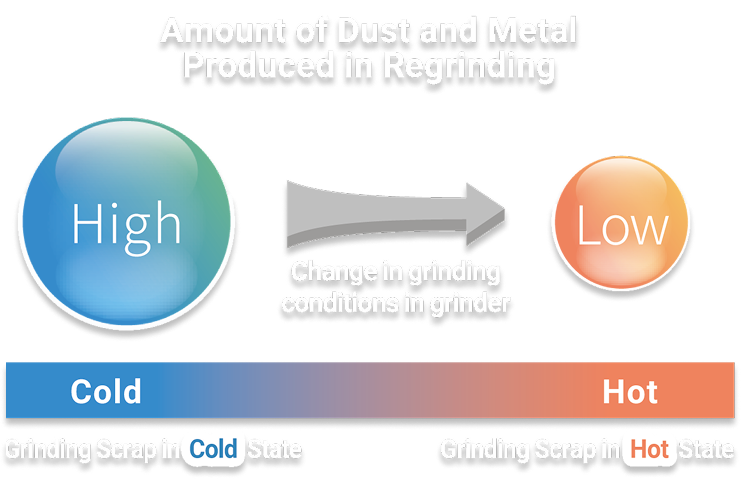

This service was launched in FY 2023, and thanks to the cooperation of our customers, we have successfully established a stable system for collecting waste plastics—one of the key challenges we initially faced. In terms of quality stabilization, we have made significant progress in metal removal technologies. By carefully selecting the appropriate grinding equipment and optimizing grinding conditions through repeated trials, we have dramatically reduced the incidence of metal contamination. In particular, for certain types of grinders, we have found that regrinding molded waste while it is still hot—rather than after it has cooled—can significantly reduce the generation of dust and metal particles. Furthermore, we are continuing to explore advanced metal removal technologies in collaboration with external partners, including the potential introduction of new removal methods.

Launching of DURANEX® rG-PBT GHB336

PBT is widely used for automotive parts, electrical and electronic parts, and other uses thanks to its superior heat resistance and electrical properties. DURANEX® rG-PBT GHB336 constitutes a marketed grade containing approximately 30% recycled PET raw materials derived from PCR materials collected from the market and helps to reduce the product carbon footprint and improve recycled raw material usage rates.

We also plan to commercially develop environmentally-friendly products made with the use of PCR raw materials in connection with other engineering plastic resins.

Customer-Focused Environmental Solutions

In addition to our work on mechanical recycling as introduced here, we are also developing all sorts of environmental solutions—from chemical recycling, biomass utilization, CO2 utilization, and the provision of products and technical services.

In order to dispel customers’ concerns about the stability of supply and quality and performance matters when it comes to environmentally-friendly products and meet their diverse environmental needs, we will continue to offer a comprehensive environmental solutions. What will help make this possible is DURACIRCLE.