Highlights 2024

Daicel Group’s New Task Force!

Daicel Group’s New Task Force!

Our Challenges in the xEV Market

In recent years, we have seen a shift to xEVs, such as plug-in hybrid EVs (PHEVs), fuel-cell EVs (FCEVs), and battery EVs (BEVs), in countries around the world. Since EVs use electricity rather than gasoline, their use leads to significant reductions in greenhouse gas and harmful exhaust emissions while they are being driven, making them environmentally-friendly and sustainable options that contribute significantly to carbon neutrality.

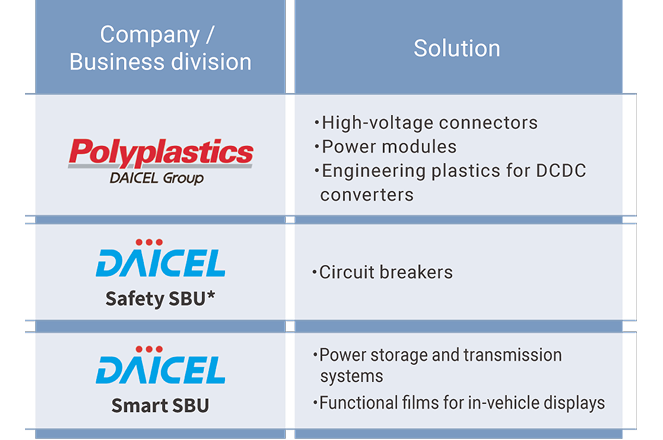

Daicel Group Launches the xEV Task Force

In order to promote the spread of sustainable xEVs, the Daicel Group has also introduced a wide range of products, including high-voltage connectors, power modules, engineering plastics for DCDC converters, circuit breakers using ONE TIME ENERGY®*1, power storage and transmission systems, and functional films for in-vehicle displays.

In the past, our efforts were limited to individual group company-level or SBU*2 approaches, and as a result, the Daicel Group was not fully able to provide optimized products and services for the xEV market as a whole.

*1: Technology employed in airbags to generate instantaneous power

*2: Abbreviation for Strategic Business Unit; refers to a business division operating within the Daicel Group

Offering Fully Optimized Products and Services

We established the xEV Task Force to enable the Group to provide comprehensive solutions to the xEV market, whose profile will continue to rise in the future, by leveraging the know-how amassed to date by each SBU and Group company and the relationships of trust that have been cultivated with our customers. This task force aims to enable the Group to become the trusted partner for customers by providing products and services fully optimized by the Daicel Group for the xEV market and creating opportunities for new business through the creation of value together with customers.

EV-Specific Challenges

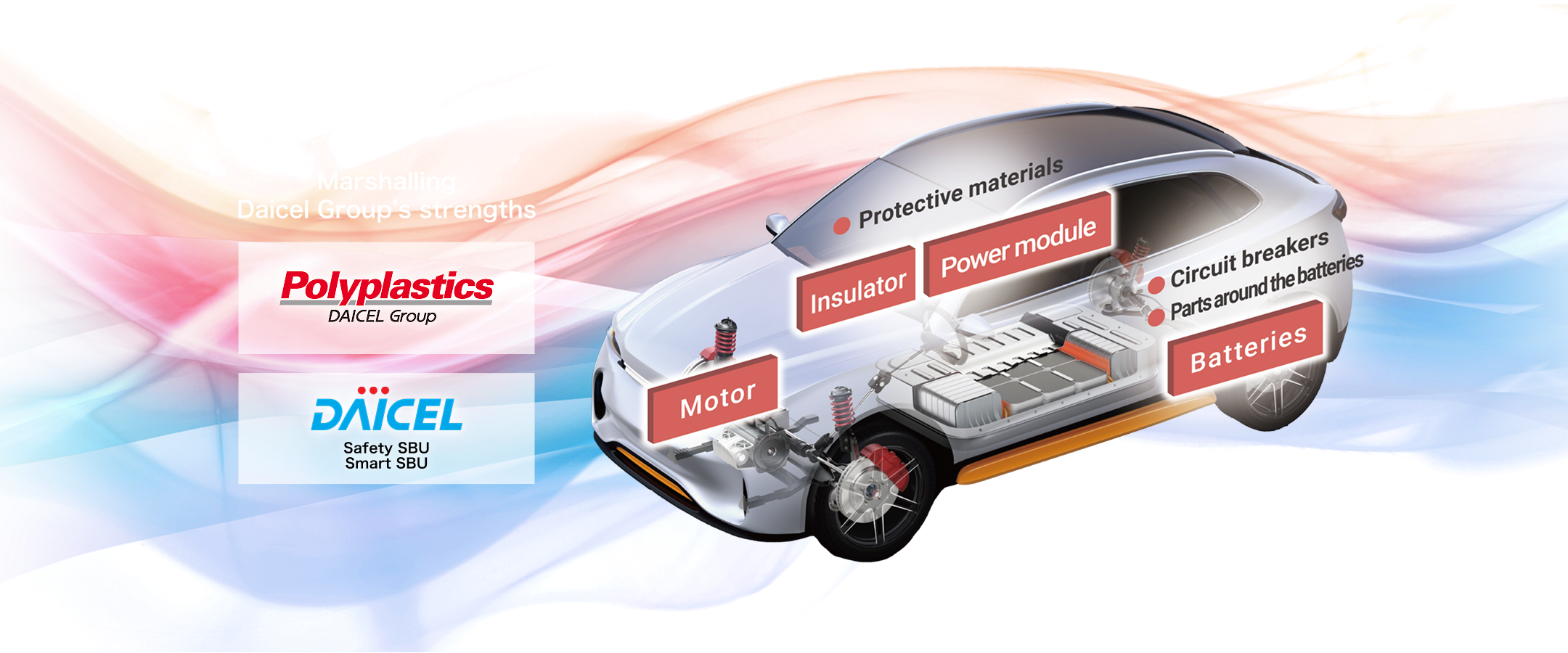

Because EVs are driven not by engines but by motors, the demand for high-heat resistant materials is declining. If anything, new needs for maintaining and managing electronic parts and systems at optimal temperature levels (thermal management) must be satisfied. In addition, EVs are equipped with high-voltage batteries, such that we need to prevent occupants from suffering electric shocks and secondary disasters from occurring in the event of a traffic accident or malfunction.

Together Toward Greater Heights in xEV with Daicel Group

When it comes to xEVs and BEVs in particular, thermal management for controlling vehicular heat is seen as something that is very important given the impact it has on fuel economy and battery performance and durability. Since thermal management in BEVs maintains the temperature around the batteries at 100℃ or less, it is possible to replace the nylon or other high-heat resistant materials typically used in gasoline-powered vehicles with POM or long-fiber polypropylene (PP). The use of POM or long-fiber PP instead of metal or PPS will lower the product carbon footprint as well as amount of energy consumed during molding.

It is possible to safely and instantaneously shut off any high-voltage and high-current batteries used in EVs with the use of a circuit breaker for which the advanced technological capabilities of ONE TIME ENERGY, a piece of technology wielded by Daicel’s Safety SBU, have been harnessed. Daicel’s Smart SBU also provides protective materials for parts, including insulators for EV motors and power modules featuring integrated power semiconductors.

Comprehensively providing safe, reliable, and highly functional products in the xEV market by marshalling such capabilities of the Daicel Group will certainly help the xEV market evolve further in the years to come.

Group-Wide Optimization of Products and Services

Contributing to a Sustainable Society and Looking to the Future

Whereas around 10 million xEVs were sold globally in 2021, this number is expected to undergo a nearly eight-fold increase to around 80 million xEVs by 2035. Nevertheless, the history of this sector has just begun. All sorts of new challenges to be addressed will likely continue to emerge, such as in terms of a lack of charging infrastructure and the time it takes to charge batteries. To further promote the spread of xEVs, solutions to these new challenges will be required.

In the future, we plan to create new value for the xEV market by working on developing new resins across Group companies and SBUs and considering partnerships with outside research and development teams.

Going forward, we will marshal the capabilities of the Daicel Group to offer comprehensive solutions for the xEV market and help realize a sustainable society through the creation of new value.