Environment and Safety

Kaohsiung Plant Cuts 1,500 t/year CO2 with Advanced Control Technology

In FY 2022, Polyplastics introduced Advanced Control Technology (ACT) to optimize process control for a part of the POM production process (TOX process) at the Fuji Plant.

This fiscal year, we took steps to introduce ACT at the Kaohsiung Plant, which also maintains a similar TOX process, in order to further accelerate the reduction of CO2 emissions for the entire Group.

At the Fuji Plant, where ACT has already been introduced, optimizing the reduction of energy consumption across all steps by controlling processes for the entire distillation process has succeeded in reducing the amount of steam produced by 34,400 tons per year (equivalent to a reduction of around 4.4% for the entire Fuji Plant). This is about 1.5 times the reduction amount expected at the time of planning and translates into a reduction of approximately 4,500 tons of CO2 per year.

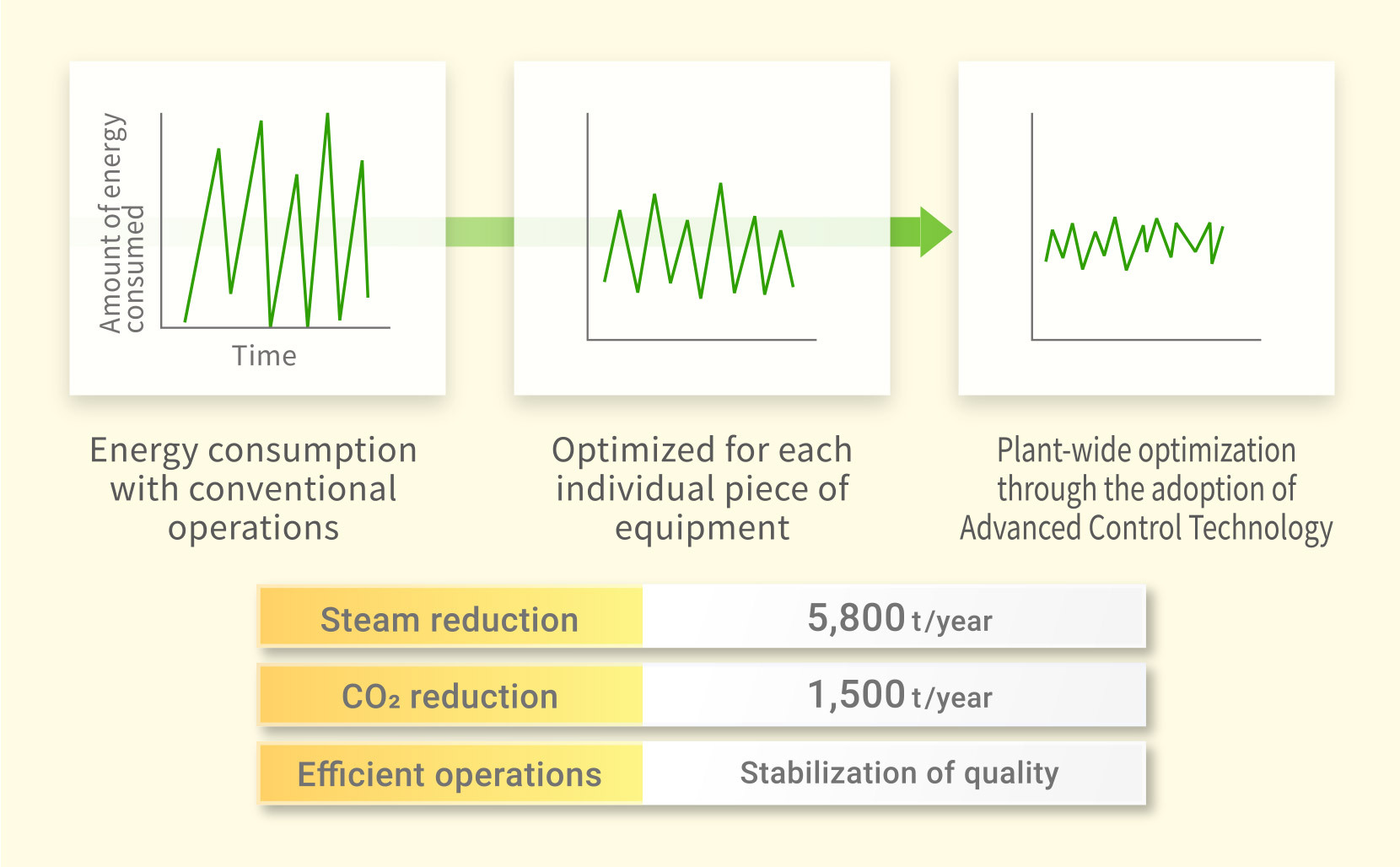

At the Kaohsiung Plant as well, the introduction of ACT is expected to reduce the amount of steam produced by 5,800 tons per year (which would translate into a reduction of 1,500 tons of CO2 per year).

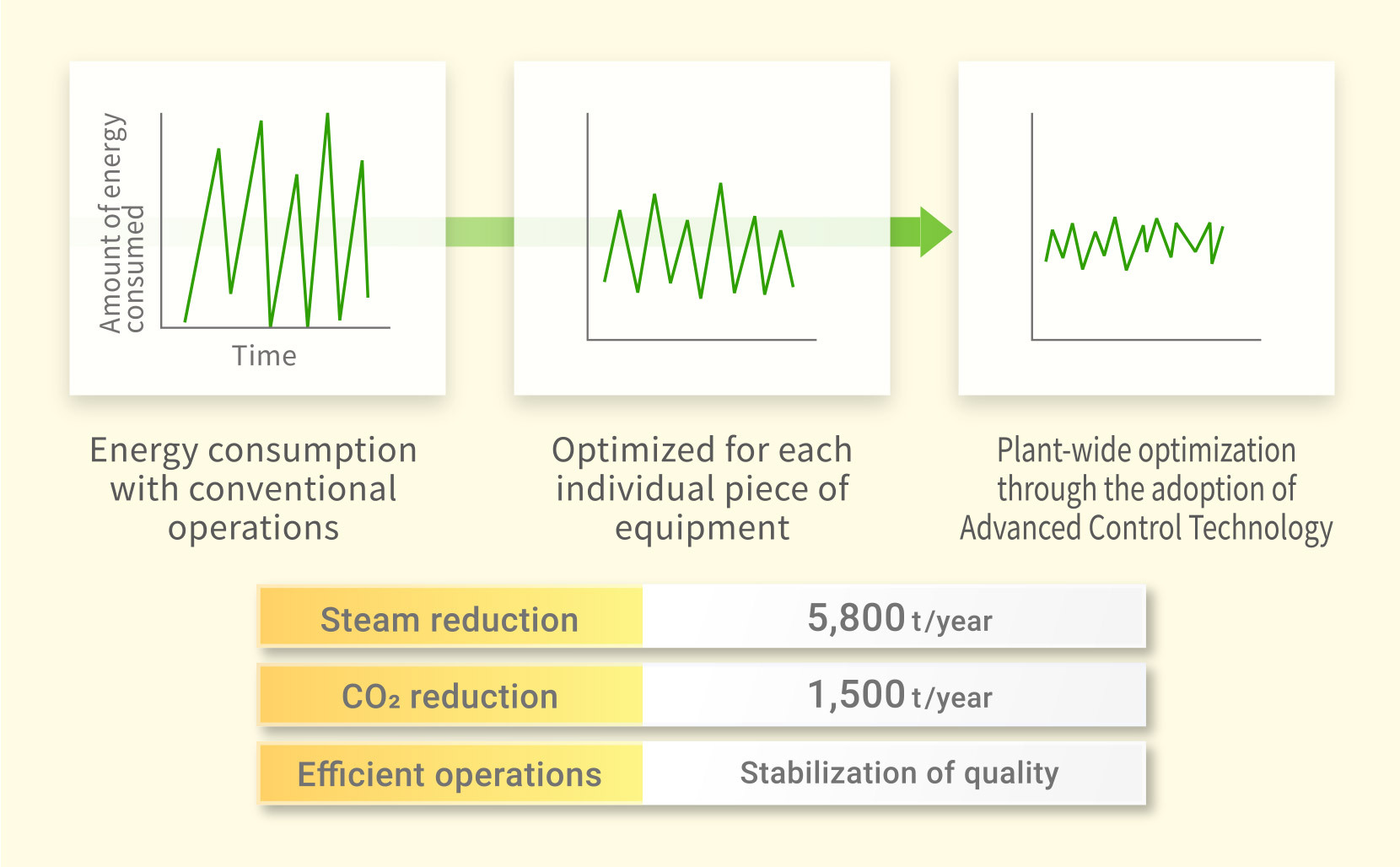

Advanced Control Technology

In a complex production process where multiple distillation columns interfere with one another, advanced control technology optimally controls the entire process to achieve efficient operations. Previously, temperature and pressure levels in each distillation column would be monitored and controlled by operators, such that optimally controlling the entire process would have been difficult even if each individual piece of equipment was operating optimally.

Through advanced control, it is possible to optimize the entire manufacturing process—not only reducing steam consumption, but also minimizing quality variations and alleviating operational burdens.

We plan to introduce advanced control technology at the Kuantan plant in FY 2025 and at our Nanton plant thereafter. Advanced control technology is used to not only reduce CO2 emissions but also help stabilize product quality and lessen the operational burden placed on work sites. Its application accelerates decarbonization and other sustainable initiatives for the entire Group.

Related Link

Project for Logistics Innovation

In recent years, many companies have found themselves facing varied and complex challenges in the area of logistics including driver shortages, demands for better working conditions, including with respect to long working hours; excessive inventory; job specialization; and the need to reduce CO2 emissions.

In order to implement optimal solutions to these challenges for the entire Group, Daicel has launched a Project for Logistics Innovation to visualize and accelerate the prioritization of issues through a logistics assessment and other actions.

Through this project, we have been working to address logistics issues across the entire supply chain, such as by improving loading rates, identifying, and reducing delivery and waiting times and incidental work, and accelerating the processing of shipping instructions. Reducing the environmental impact is an important theme among such logistics issues. Improving loading rates in particular is directly tied to efforts to improve transportation efficiency, the attainment of which is expected to reduce CO2 emissions.

To successfully improve the loading rates, it is essential to gain the cooperation of our customers who receive the shipments, in addition to our own initiatives. As such, we have faced challenges in achieving significant progress. However, we were able to improve loading rates this fiscal year by engaging in repeated discussions and building a system of cooperation with our customers.

Previously, goods were often shipped without fully loading the trucks. By reducing the frequency of orders and deliveries, we were able to improve transportation efficiency and thereby help reduce CO2 emissions.

Topics

Reducing in CO2 Emissions by Improving the Transport Loading Rate

In one example in which loading rates were improved, there was an issue where many deliveries were being made without loading trucks to full capacity.

In order to resolve this issue and ensure efficient deliveries, we asked customers to aggregate delivery dates and optimize the allocation of trucks through the introduction of the truck allocation system and held repeated discussions to achieve this goal.

Our customers agreed with our proposal and made it possible to reduce the frequency of deliveries from once daily to once every other day. This outcome led to improved transportation efficiency as well as reduced CO2 emissions from transportation.

In the future, we aim to work not just on our own but also collaborate with other Daicel Group companies to realize joint delivery and joint warehousing initiatives and will strive to evaluate efficiency by ascertaining and analyzing data on material amounts, inventory data, and logistics costs. We also plan on streamlining operations by reducing overseas deliveries and harnessing analytical tools in concert with the operations of our overseas plants and will develop proactive reforms in the area of logistics for the realization of sustainable logistics.

Introducing Solar Water Heaters

Reducing CO2 Emissions by 120 tons/year through the Optimization of Operating Conditions

At the Oberhausen Plant (in Germany), the operating conditions needed to refine raw materials in the COC polymerization process had been uniformly applied across all grades.

This fiscal year, the attempts to optimize operating conditions for each individual grade through the use of historical data, simulations, and actual testing and analytical data have led to reductions in the consumption of natural gas, which is used to heat the thermal medium. This allowed us to successfully reduce CO2 emissions by approximately 120 tons, around double the amount by which we had originally expected to reduce CO2 emissions. We will continue to work toward reducing the environmental impact across the entirety of our Group.

Environmental Monitoring Conference

At the Environmental Monitoring Conference held at the Fuji Plant every June, we explain the environmental efforts of the Fuji Plant to local residents, exchange opinions, and have them tour the environmental facilities within the plant. In FY2024, 13 representatives from six neighboring districts participated.

Comments

After taking a tour of the plant and listening to the environmental report for FY 2023, we were reminded of the unprecedented care that has been taken in carrying out initiatives concerning the environment and safety. We also heard from local residents that they hardly ever perceive odors unlike the way it used to be. During our tour of the plant, we truly felt that there was really very little in the way of problematic odors and that one could live more safely and with greater peace of mind than before. Moreover, the company has also been cooperating yearly with efforts to collect trash in local areas and expect that they will continue to work on environmental causes while partnering with the local community.